So Elpro increased its capacity with the help of Rittal and Eplan

The Alingsås-based company Elpro is building control cabinets for the machine industry. A task that places high demands on both planning and production.

Before 2020, Elpro made a major change, moved to new, larger premises and invested in production optimization. In the investment, they bring with them both Rittal and the sister company Eplan to enable automation of their work processes.

Automation is, to say the least, a hot topic in many industries. But, if you look at electrical construction as an industry, it is not known to be at the forefront when it comes to automation or digitization. The investment that Elpro has now made together with Rittal and Eplan is therefore relatively unique in the industry.

– There is a great quality thinking in this project. Quality is extremely important in our work and there is very little room for error. That is why it is extra important that our production process is as safe and efficient as possible, says Jesper Ottoson, CEO of Elpro.

Elpro offers its customers a comprehensive service that includes the entire process from concept development and production of components to actual production and installation. A workflow that before the investment was largely handled manually.

– The previous manual process meant that in the quotation stage when we create all the basis for a potential production of a control cabinet, we made qualified guesses about components. Then we had to find those components to be able to create the substrate. With the help of Eplan, we now have a design system with access to all components and articles via Eplan Dataportal inside the software. What used to be manual is now digital and we basically eliminate the risk of error we previously had and are one step ahead already in the quotation stage, says Jesper.

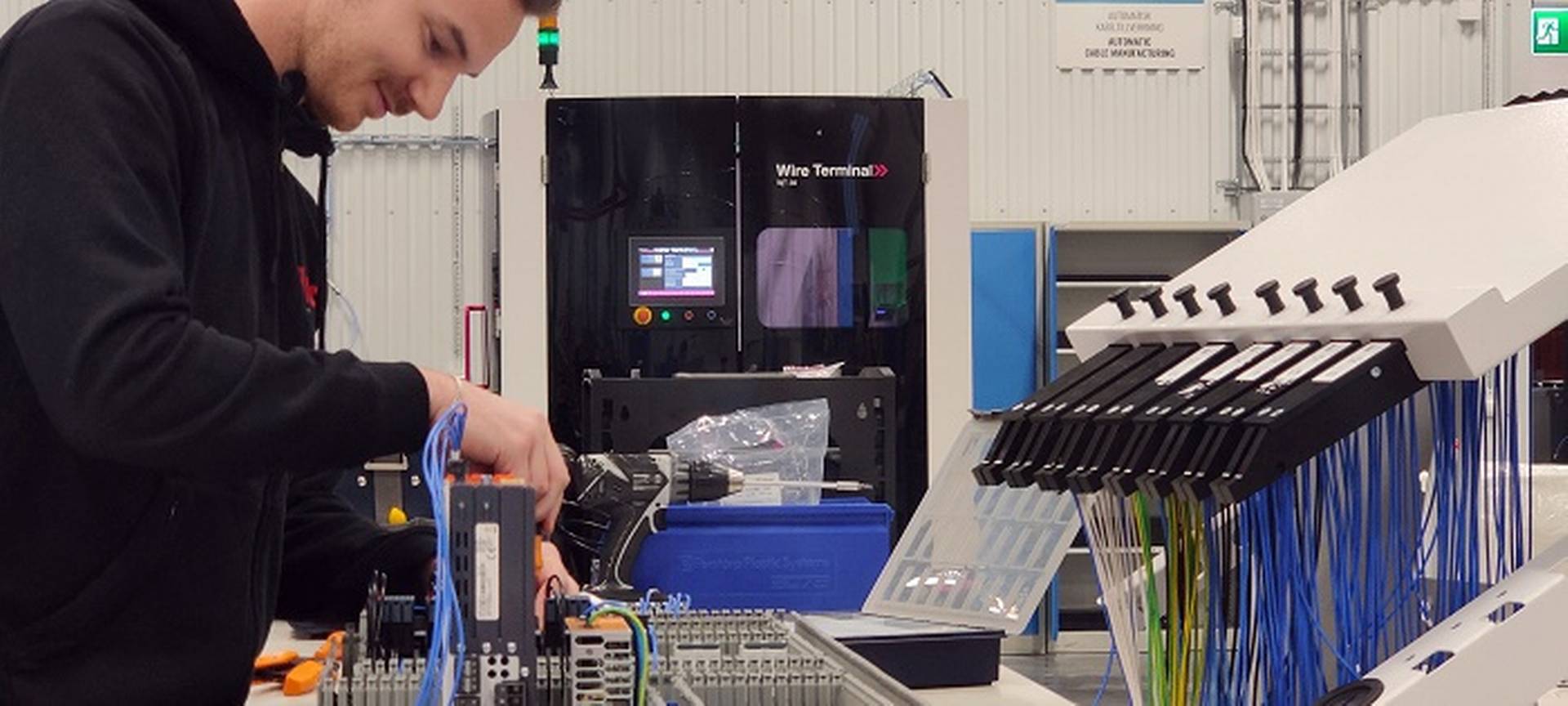

In Eplan’s platform, Elpro also uses a service called Smart Wiring. It is a software for visualizing wiring in the manufacture of control cabinets. It acts as a virtual assistant and provides all the information needed from the connection point to the exact wiring. It then communicates with Rittals Wire Terminal. A product that has also automated Elpro’s production.

– Rittals Wire Terminal has enabled us to increase our production without increasing our staff and at the same time reduce the workload of our existing staff. We wanted to put the tools on the shelf and we really had to do that. It contributes to a good time saving. Another positive consequence of this new process is that we have reduced our waste of cable scrap a lot, says Jesper.

Through Eplan and Rittal’s solutions, Elpro has been able to modernize its production and thereby streamline, automate and quality assure its work. Next, Jesper and the rest of Elpro look forward to automating more parts of the process and continuing to grow.

– We are very happy and satisfied with the collaboration with Rittal and Eplan. It has opened up new paths forward and now we want to automate more parts of our workflow, such as drilling holes. We can increase our capacity now while reducing our risks. It clearly creates a simpler starting point for new, exciting goals, Jesper concludes.

In combination, Rittal and Eplan become a complete partner for those who want to optimize their value chain. Every step in the process from technology, purchasing and manufacturing to operations and IT can be streamlined. Do you want to know more about Rittal and Eplan’s solutions? Then you will find it here.